Plastic injection

At GB Inyectados we have been working for over 25 years in plastic injection.

Plastic moulding

We manufacture personalised prototypes and pieces from plastic pellets, and also take charge of other phases related with the project such as assembly and finishing. We offer a quick, efficient, customised mechanised industrial service.

If you can imagine it, we can make it a reality.

If you can imagine it, we can make it a reality

Lower cost, greater speed and complete service

The piece is obtained in a single step, thereby reducing the cost of manufacture. We work quickly so that our clients do not stop their production chains. We advise you from your first idea until the final completion of your project.

Control, maintenance and delivery times

We work with suitable, phthalate-free materials such as TPE, ABS, NYLON, Butadiene, K-Resin, PP, PE, PS, etc. At all times we supervise the work processes, equipment and each piece to ensure the quality of our products.

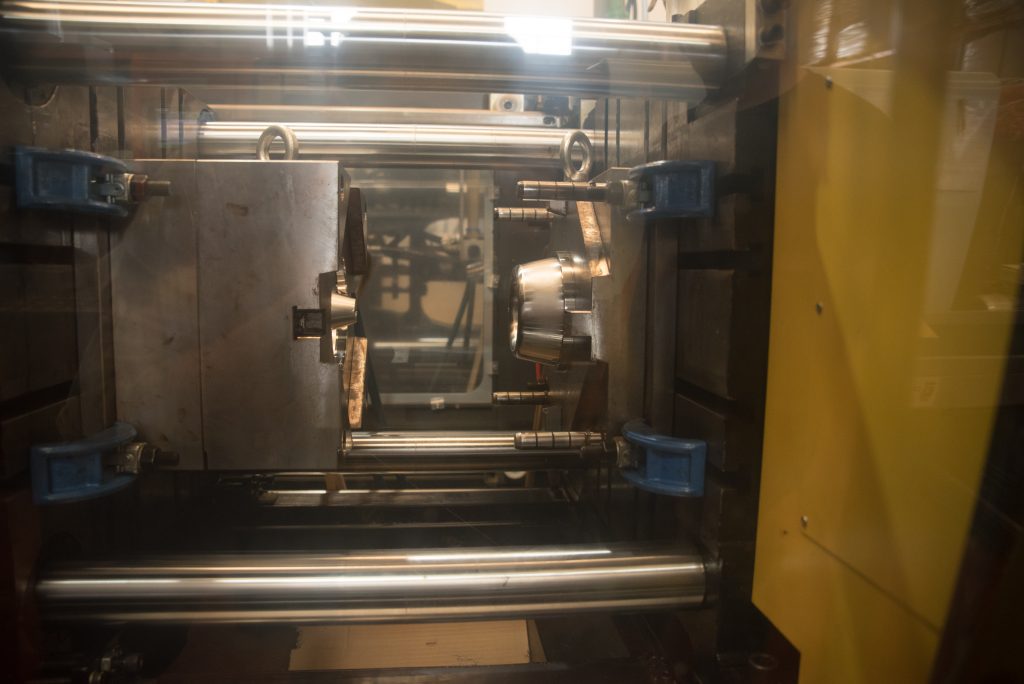

Own machinery with the latest technology

We have a fleet of our own specialised, innovative machines to offer quality results. We offer personalised solutions for manufacture, design and prototypes for each client.

Recycled materials

One of our objectives is to collaborate with environmental improvement, therefore we work with recycled materials. We manufacture for the hydrosanitary, toy, sport, agriculture and home sectors, among many others with chain production.

What moulding by plastic injection involves

It is a process for manufacturing and moulding pieces in large quantities and in a single run with the objective of reducing costs. In terms of the method, plastic injection moulding is the technique that melts plastic pellets to fill a mould through an injection needle. Once cooled, it solidifies to achieve the final result.

At GB Inyectados we work with plastic injection moulds with different shapes, sizes, thicknesses and measurements. Additionally, we take care to ensure that all steps of the process are correct.

There is therefore a person who supervises the filling of plastic in the moulds and the result obtained, in addition to the aesthetic and quality.

Manufacturing steps followed at GB Inyectados

1. Product design and development.

We design the product with the specifications of the client or work on a design that they provide us.

2. Prototyping phase of 3D designs.

We create 3D prototypes of the moulds before creating the mould itself. This way, we ensure that measurements, shape and needs are checked and monitored.

3. Design and development of moulds for plastic pieces.

We create the mould taking the prior prototype into account, always guaranteeing the quality and durability required.

4. Injection of thermoplastics.

We carry out the injection for chain production of the product. We also offer other methods related with the product such as assembly, screen printing, chromium plating, painting, pad printing, metallisation, etc.

One of the great advantages of injection moulding is that,

if necessary, we redesign your product to improve it continuously.

Within one company we design, manufacture and prepare your product.

Factors to take into account in plastic injection

Speed

The melted plastic is input into the mould quickly for cooling and moulding. It is therefore recommended for this process to be as quick as possible.

Temperature

The melted plastic is input into the mould quickly for cooling and moulding. It is therefore recommended for this process to be as quick as possible.

Pressure

The weight of the mould on the material also affects the final form and finish.

Injected plastic pieces

We manufacture all types of pieces through plastic injection. We offer all types of shapes, geometries, sizes, measurements and colours. We take charge of understanding your project in detail to manufacture the piece that really meets your needs.

We have our own machinery, with which we can carry out all types of industrial injection or blowing. Additionally, we follow strict quality controls to offer you resistant, durable pieces.

Advice on injected plastics

We work together to offer you the best solution through our thermoplastics injection services.

At GB Inyectados we use recycled and ecological plastic materials. We advise and guide you to choose the best type of plastic for your project. Depending on the type of piece or product you wish to manufacture, our technical team will offer you one material or another, always recycled and ecological.

Advice on the manufacturing method

Our services form part of a large scale industrial design and manufacturing process. Each injection moulding machine works with personalised moulds custom made for each client.

Therefore, our team advises you from the first moment to achieve the best result in the manufacture of your product. We help you from design to the final finish.

Manufacturing by injection moulding

At GB Inyectados we make your idea a reality, creating it from scratch through the plastic injection process. To do so, we advise you on design, packaging, labelling and delivery.

We have worked in the sector for 25 years making our clients’ products a reality. We are the solution for creating your product.

We make our clients’ ideas a reality.

We go from “I have a product to solve a problem” to its production chain and distribution. We take charge of everything from the first moment; you will not lost time or have to worry about anything.

Contact us and tell us your idea. We will manufacture it through thermoplastic injection.